In the oil and gas industry, maintaining efficiency, safety, and reliability is critical. One of the

key technologies that helps achieve these goals is the Programmable Logic Controller (PLC).

PLCs are integral to automating processes, monitoring equipment in real time, and ensuring

the safety of operations. In this article, we explore the importance of PLCs in the oil and gas

sector, their wide range of applications, and how digital solutions like FAT FINGER can further

enhance their effectiveness.

A Programmable Logic Controller (PLC)is an industrial digital computer designed to

control automated processes and machinery. In the oil and gas sector, PLCs are pivotal in

regulating a variety of processes, from drilling and production to transportation and safety

systems. They serve to automate operations, ensure smooth monitoring, and improve

overall process efficiency, all while minimizing human error.

PLCs automate repetitive and complex processes, reducing the need for manual intervention.

This not only speeds up operations but also ensures consistency and minimizes human error.

For instance, PLCs can control the entire drilling process, from initiating pumps to managing

rig operations.

One of the most valuable aspects of PLCs is their ability to continuously monitor equipment

and operations. This real-time data collection helps operators quickly identify any issues,

such as equipment malfunctions or hazardous conditions, allowing for swift intervention and

minimizing downtime.

The oil and gas industry is inherently dangerous, with various risks to workers and the

environment. PLCs play a vital role in automating safety processes, such as emergency

shutdown systems and pressure monitoring. By ensuring strict adherence to safety protocols,

PLCs help reduce accidents and improve the well-being of workers.

PLCs are used in a variety of areas within the oil and gas industry. Here are some key applications:

In drilling operations, PLCs control and monitor drilling rigs, including parameters like pressure,

temperature, and depth. By automating the drilling process, PLCs help ensure accurate, safe,

and efficient operations, reducing the risk of errors and improving operational outcomes.

PLCs manage processes in production and processing facilities, such as separating oil from gas,

refining, and transporting products. They ensure that each stage of production runs smoothly,

helping optimize yield, reduce energy consumption, and maintain high product quality.

PLCs are crucial for monitoring the flow, pressure, and temperature of oil and gas during

transportation via pipelines. They also detect potential leaks and anomalies, triggering safety

mechanisms to prevent accidents and minimize environmental risks.

Safety is paramount in the oil and gas industry. PLCs help maintain high safety standards by

automating safety-critical operations like emergency shutdowns, equipment protection, and

hazard detection. However, the complexity of the industry also poses challenges:

· Human Error: Despite technological advances, human error remains a leading cause of

accidents.

· Inconsistent Safety Checks: Regular safety checks are essential to identify potential

hazards before they become significant problems.

· Data Overload: The vast amounts of data generated by PLCs and other systems can

be overwhelming for operators without the right tools to manage and analyze it.

While PLCs automate many tasks, safety and efficiency can be further enhanced with digital

workflows. FAT FINGERoffers digital solutions that help companies in the oil and gas sector

streamline their safety operations, reduce human error, and ensure compliance with safety

standards.

· Take 5 Safety Checklist: This tool allows workers to assess potential hazards before

performing any task, ensuring proactive safety measures are in place.

· Near Miss Reporting: By documenting near-miss incidents, workers can help identify

patterns and make adjustments to prevent future accidents.

· Job Hazard Analysis: FAT FINGER’s digital platform helps identify and assess hazards

related to specific tasks, ensuring that proper safety measures are implemented.

· Incident Reporting: This feature enables real-time reporting of accidents, ensuring

that corrective actions are taken swiftly to prevent recurrence.

Several oil and gas companies have successfully integrated FAT FINGER's digital workflows to

enhance safety and operational efficiency.

Case Study 1: Improving Drilling SafetyA leading oil company adopted the Take 5 Safety

checklist to proactively identify potential hazards during drilling operations. This practice led to

a significant reduction in accidents and improved safety performance.

Case Study 2: Streamlining Incident ReportingAnother oil and gas operator used

FAT FINGER’s Incident Reporting feature to streamline their reporting process. Real-time updates

allowed them to address safety concerns immediately, reducing downtime and increasing overall

safety.

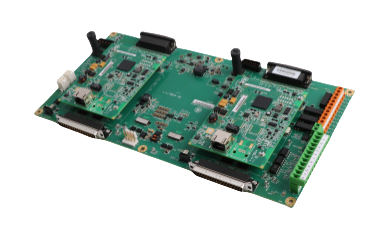

Example Modules of GENERAL ELECTRIC

IS215VPROH1BD

]The GE IS215VPROH1BD Communication Module is a pivotal component in the evolution of

industrial automation, offering unparalleled reliability and efficiency. Its compact design,

coupled with its robust communication capabilities, makes it an indispensable addition to

any industrial system.

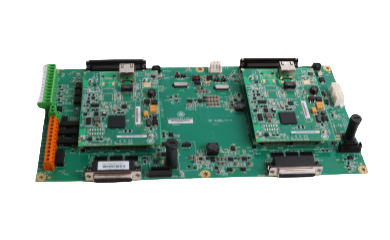

IS215REBFH1BA

The General Electric IS215REBFH1BA Control Board is a cutting-edge solution for turbine

control systems, offering unparalleled precision and reliability. It seamlessly integrates with

various industrial settings, providing seamless communication through advanced interfaces

like RS-485 and Ethernet. Its robust design ensures stable operation across a wide

temperature range (-40°C to +70°C), making it ideal for demanding environments.

Equipped with 16 input and 8 output channels, this control board supports extensive

data acquisition and process control. It is compatible with leading control protocols

such as MODBUS RTU and CANopen, facilitating compatibility with a broad range

of industrial automation systems.

IS215VCMIH2B

IS215VCMIH2B is a VME Communication Interface Card manufactured by General Electric

as part of the Mark VI Series used in gas turbine control systems. The VME Bus Master

Controller (VCMI) board serves as the communication interface between the controller

and the I/O boards as well as the communication interface to the IONet system control

network. The VCMI also serves as the VME bus master in the control and I/O racks,

managing the IDs for all of the boards in the rack and their related terminal boards.

Through the J301 backplane connector, the VCMI card receives analog and digital

feedback on power status.

PLCs are indispensable in modern oil and gas operations, helping automate processes, monitor

equipment, and ensure safety. However, the integration of digital workflows like FAT FINGER can

take safety and operational efficiency to the next level. By leveraging these tools, companies

can reduce human error, improve real-time data analysis, and streamline compliance with

safety protocols.

If you’re ready to enhance your safety workflows and improve overall efficiency, consider exploring

FAT FINGER’s digital solutions. Start by creating a free safety workflow or request a demo to see

how FAT FINGER can work for you.