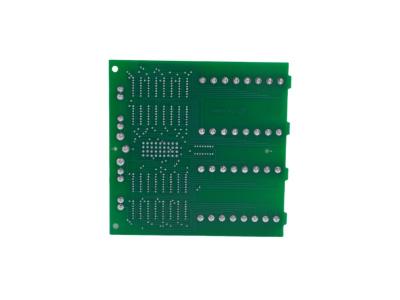

The 3500/22M Transient Data Interface (TDI) is the interface between the 3500 monitoring system and compatible software (System 1 Condition Monitoring and Diagnostic software and 3500 System Configuration software). The TDI combines the function of a 3500/20 Rack Interface Module (RIM) with the data collection capability of a communication processor such as TDXnet.

The TDI resides in the slot adjacent to the power supplies of a 3500 rack. It interfaces with M series monitors (3500/40M,3500/42M, etc.) to continuously collect steady state and transient dynamic (waveform) data and pass this data through an Ethernet link to the host software. Refer to the Compatibility section at the end of this document for more information. Static data capture capability is standard with the TDI.

However, using an optional Channel Enabling Disk will allow the TDI to capture dynamic and high-resolution transient data as well. The TDI incorporates the communication processor function within the 3500 rack.

Although the TDI provides certain functions common to the entire rack, it is not part of the critical monitoring path and has no effect on the proper, normal operation of the overall monitor system for automatic machinery protection. Every 3500 rack requires one TDI or RIM, which always occupies

Slot 1 (next to the power supplies).

The 3500/22M Transient Data Interface Module is a vital component in Bently Nevada’s 3500 series, designed to capture and process transient data from industrial machinery. Offering advanced capabilities for monitoring machine conditions, the 3500/22M ensures accurate and real-time measurement of transient events, such as sudden vibrations or shocks, that may indicate potential issues within the system.

Built with precision and reliability, the 3500/22M works seamlessly with other 3500 modules to provide comprehensive machine health monitoring. It captures high-resolution data during transient events and stores it for further analysis, enabling engineers to identify problems early and avoid unexpected downtime. The 3500/22M interfaces with a wide range of sensors and delivers critical data to predictive maintenance systems.

For the quick assistance message us on WhatsApp at

For the quick assistance message us on WhatsApp at