IC200ALG620 Product datasheet

|

Model number: |

IC200ALG620 |

|

Module Type: |

VersaMax IO is versatile Modular |

|

Manufacture: |

GE |

|

Condition: |

Brand New |

|

Range of Product: |

VersaMax |

|

Lead time: |

In Stock |

|

Weight: |

0.3 kg |

|

HS CODE: |

8537101190 |

|

Dimension: |

15.5x15x8.3cm |

|

MOQ: |

1 |

|

Product Origin: |

USA |

|

System: |

PLC |

|

Discontinued on: |

Active |

|

Communication Service: |

Ethernet router |

IC200ALG620 Functional Description

The IC200ALG620 is an advanced analog input module from Emerson Automation, designed to accommodate a wide range of Resistance Temperature Detectors (RTDs) for precise temperature measurement. This 4-channel module offers compatibility with a variety of RTD sensors, including those with resistance values of Platinum, Copper, Nickel, and Nickel/Iron in different configurations such as 3-wire and 4-wire setups. The module features a high-resolution 16-bit Analog to Digital Converter (ADC) per channel, ensuring accurate readings with a temperature measurement precision of ±0.15% at 25°C.

The IC200ALG620 Analog Input RTD Module also includes advanced fault detection capabilities, including the ability to identify open RTDs, wiring faults, and alarm conditions such as overrange, underrange, and input shorts. These faults are directly reported to the host Programmable Logic Controller (PLC), enabling seamless integration into automation systems. Additionally, the IC200ALG620 Analog Input, 16 Bit RTD 4 Channels is equipped with LED indicators to show real-time system status, including a green "OK" LED for proper operation and an amber LED for fault detection.

Operating at a voltage of 5V, the IC200ALG620 On Sale Large Stock Plc Controller supports an update rate of 210 ms per channel at 60Hz and 230 ms at 50Hz. It draws 125 mA of current at both 5.0V and 3.3V bus outputs. The module is also protected by impressive isolation ratings: 250V AC isolation for user input to logic, and 1500V AC isolation for user input to frame. This ensures the module's reliability and robustness in various industrial environments.

With a temperature rating of up to 60°C, the IC200ALG620 is designed for reliable performance in clean environments, and its ease of installation further simplifies integration. Proper grounding during installation is essential to prevent electrical damage and ensure optimal performance of this versatile module in any industrial automation setup.

If you have other request contact our team to get customized service

Call +86 18159889985 to be connected with our Manager Stella

Call +86 18159889985 to be connected with our Manager Stella Email to sales6@apterpower.com get your best quotation

Email to sales6@apterpower.com get your best quotation For the quick assistance message us on WhatsApp at +86 18159889985 now!

For the quick assistance message us on WhatsApp at +86 18159889985 now!

|

GE |

IC693ACC310 |

GE |

IS220PPDAH1B |

GE |

IS220PAICH2A |

|

GE |

IC693ACC302 |

GE |

IS220PPDAH1A |

GE |

IS220PAICH1A |

|

GE |

IC676PBO082 |

GE |

IS220PGENH1AE |

GE |

IS230JPDMG1B |

|

GE |

IC693ALG442 |

GE |

IS220PDOAH1B |

GE |

IS220YDOAS1AJ |

|

GE |

IC693ALG391 |

GE |

IS220PDOAH1A |

GE |

IS220YDOAS1A |

|

GE |

IC693ALG222 |

GE |

IS220PDOAH1A |

GE |

IS220YDIAS1AK |

|

GE |

IC676PBI008 |

GE |

IS220PDIAH1AD |

GE |

IS220YDIAS1A |

|

GE |

IC670PBI001 |

GE |

IS220PDIAH1A |

GE |

IS220YAICS1A |

|

GE |

IC670MDL740 |

GE |

IS220PAOCH1BE |

GE |

IS220UCSAH1A |

|

GE |

IC670GBI102 |

GE |

IS220PAOCH1A |

GE |

IS220PVIBH1A |

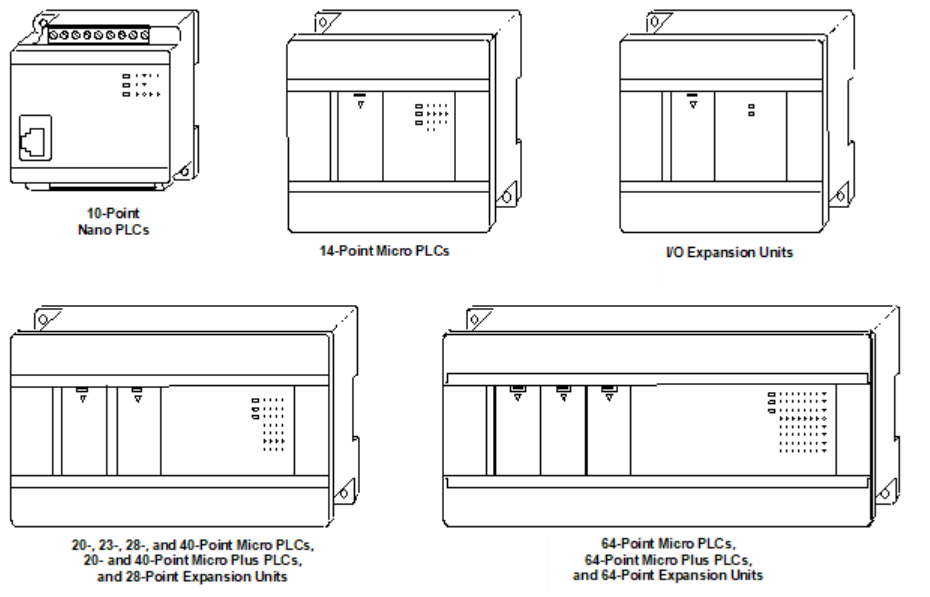

VersaMax Micro, Micro PLUS and Nano PLC Models

Introduction

Versions of these compact, powerful controllers are available for AC and DC power, and with several different combinations of discrete and analog input and output points. This chapter compares the features of the many VersaMax Nano, Micro and Micro PLUS PLC models that are available. Micro PLUS 20/40/64 CPUs have enhanced memory compared to earlier versions of these CPUs. Firmware versions 4.00 and later cannot be used with the earlier hardware versions.

The VersaMax® PLC family of products includes a broad range of small-size programmable logic controllers (PLCs) with big-PLC features. The VersaMax family includes Nano PLCs (10 points), Micro PLCs (up to 176 I/O points), and Micro PLUS PLCs (up to 320 I/O points) using optional Expansion Units. These small PLCs are the perfect solution for applications such as packaging machines, dispensing machines, and relay replacement.

Changes to the program that do not modify the size of the program are considered wordfor-word changes. Examples include changing the type of contact or coil or changing a reference address used for an existing function block. Changing an operand is usually a word-for-word change. A word-for-word change can be made and downloaded to the PLC while online in programmer mode without having to download the entire block of logic.